Shop Fabrication

Building 1 Fabrication Shop's primary function is the specialty fabrication of piping sections and assemblies.

Our direct fabrication facilities include two (2) buildings totaling over 15,000 SF with an additional 6,000 SF available for special projects.

Meccon employs only Local #597 Pipefitter Welders for our fabrication work and produces UA stamped piping systems and equipment skids.

We employ welders certified on all carbon steels, titanium, chrome alloy, nickel, hastelloy, steels (304, 316, Carpenter 20, 2025, 904L, etc.) and aluminum. Code Work – ASME PP&S Stamps B31.1, B31.2 and B31.3. Welding procedures include MIG, TIG and orbital.

Fabrication projects that we have completed include the following:

- O'Hare International Airport Ring Tunnel Ball Joint Replacement 24" C.S. Piping

- Amoco – PIA Expansion Titanium Piping

- Amoco – Waste Treatment 36"Ø SS Piping

- Sun Chemical (MI) – 3"–30" CS & SS Piping

- U.S. Steel – 84" Heavy Wall C.S .Hydraulic System

- Midway Airport Jet-A Fuel Tank Farm

- Acme Steel – 6" & 8" DBL XH 316SS

- U.S. Steel – Desulfurization 36" & 48" C.S. (All mitered fittings)

- O'Hare International Airport – 8" & 10" Jacketed C.S.

- Dow Chemical Co. – Reactor #5 3", 4" & 6" Sch. 10 316 SS Process Piping

- Fox River WWTP – 20" & 24" Sch. 10 316 SS Piping

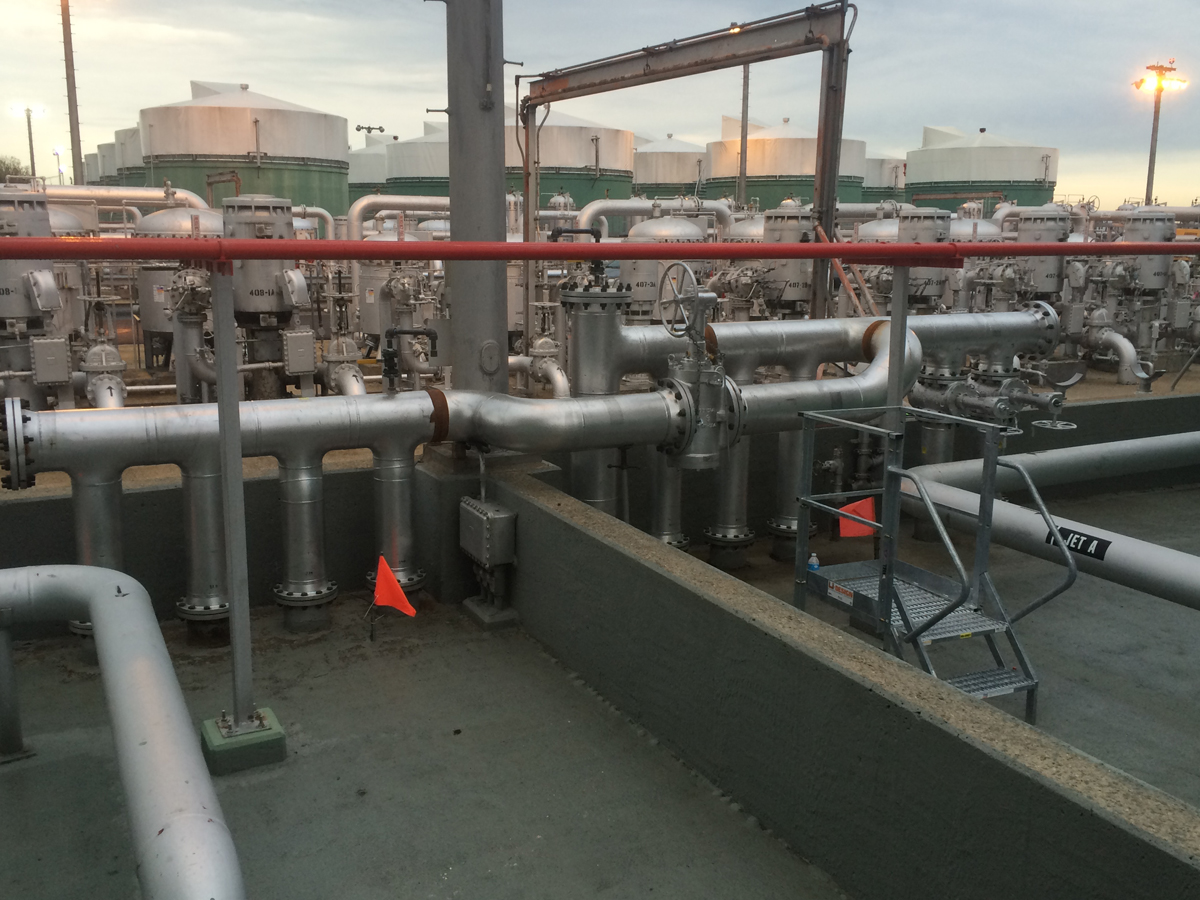

- JFK Airport Satellite Fuel Farm Tank Manifolding

Allied Aviation/ PANYNJ

JFK International Airport

Satellite Fuel Farm Tank Manifold Project

Meccon was hired by Allied Aviation (fuel system operator) and the PANYNJ to manifold the existing 60 tanks at the satellite fuel farm at JFK International Airport. After measuring the existing flanges, we fabricated spool pieces to tie into the flanges. Since this is the storage for each terminal Meccon had to layout the pieces, shop fabricate, test & paint prior to the installations of the spools. Meccon had 11 spools to install in 10 nights. We had an 8 hour window where there was no fueling at the terminal and cut off the main supply to that terminal. We were successful and had no fueling delays. Meccon was on time and on budget with a successful completion.

- Project Completion: September 2015