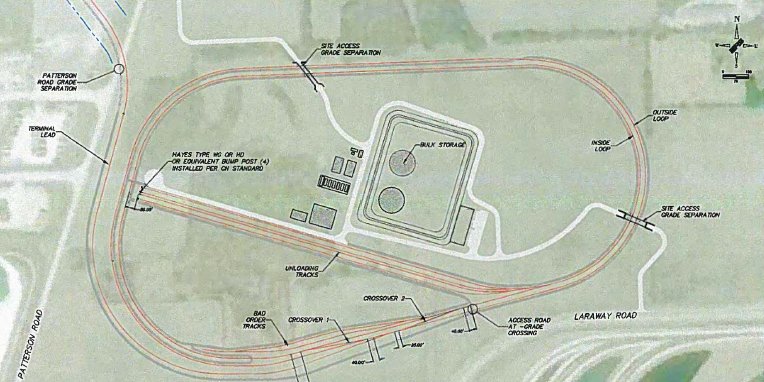

Joliet Bulk, Barge & Rail

Laraway Terminal – AG Bulk Oil Piping

Procurement and installation of a turn-key off-loading to two (2) 150,000-barrel storage tanks and loading to a local refinery pipeline. This scope of work consisted of the installation for over 3,500 linear feet of pipe ranging from 32" thru 2" both aboveground and belowground. This including the installation of support structures to hold piping above ground and the massive amount of concrete poured to set them in place.

We provided the pouring of concrete for setting of all of the major equipment with engineering lift plans for 3-meter skids, 1-prover skid, 8-vertical pumps and other miscellaneous equipment. The setting of the vertical pumps was a very precise installation with very close tolerances that had to be very detailed from the boring of the ground, to the exact support from the concrete design needed, and the actual alignments of the pumps.

The project also required the installation of a steam and condensate system to support a heating coil installed in the tank to support the oil viscosity. We supported the installation of the fire foam suppression system for both tanks. With our knowledge base around this being the first facility of its kind locally, we are presently still supporting the day to day operations for the new owner.

- Project Completion: April 2015